資源中心

Microwave/RF assemblies for military and civil aircraft from W. L. Gore & Associates are engineered with rugged features to maintain signal integrity even with the mechanical stress of vibration, acceleration loads, installation and maintenance.

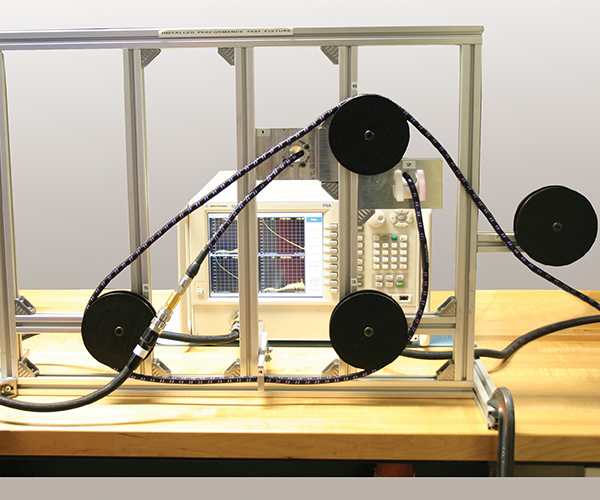

With Gore's cable installation simulator, military and civil aircraft manufacturers can be confident they're getting a reliable cable assembly solution that withstands the rigors of routing and reduces the total cost of ownership.

Answers to frequently asked questions about GORE? Microwave/RF Assemblies.

Our cables and materials have participated in decades worth of civil and defense aircraft programs. We offer a wide selection of high-speed data cables, microwave/RF assemblies, airframe sealants, and more.

Part Number Information: GORE? Microwave / RF Assemblies

Part Number Information

Gore part numbers consist of a minimum of 12 and a maximum of 15 alphanumeric characters. Groupings of these characters have a specific meaning.

When choosing military aircraft components, lasting performance is always a top consideration. Yet while many cables perform dependably prior to installation, the challenges of routing leave them damaged and ill-prepared for the rigors of the aircraft’s flight envelope. That’s why W. L. Gore & Associates developed an installation simulator to prove their microwave assemblies delivered the same reliability before and after installation.

W. L. Gore & Associates examines constraints that may have an impact on cable performance. Also examined is the process involved in selecting the right materials based on sufficient testing to verify cables will survive and perform reliably in the harshest environments.

Technical Paper: Aircraft Weight Savings through Innovative Materials Science & Unique Cable Designs

White Papers

Aircraft weight savings is an important design and modernization consideration to increase payload, fuel efficiency, range and time on station. W. L. Gore & Associates offers reliable solutions that reduce the size and weight of copper, fiber optic and coaxial cables.

Modern civil and military aircraft depend on quality microwave assemblies like those produced by W. L. Gore & Associates for reliable performance. Yet the challenges of installation in tight airframe environments can often degrade lower-quality cables, requiring replacement long before the expected end of life. In Gore’s White Paper: Reducing Life Cycle Costs with Reliable Airframe Microwave Assemblies, we take a closer look at how higher-quality cable assemblies deliver lower costs, greater productivity, and a host of additional benefits.